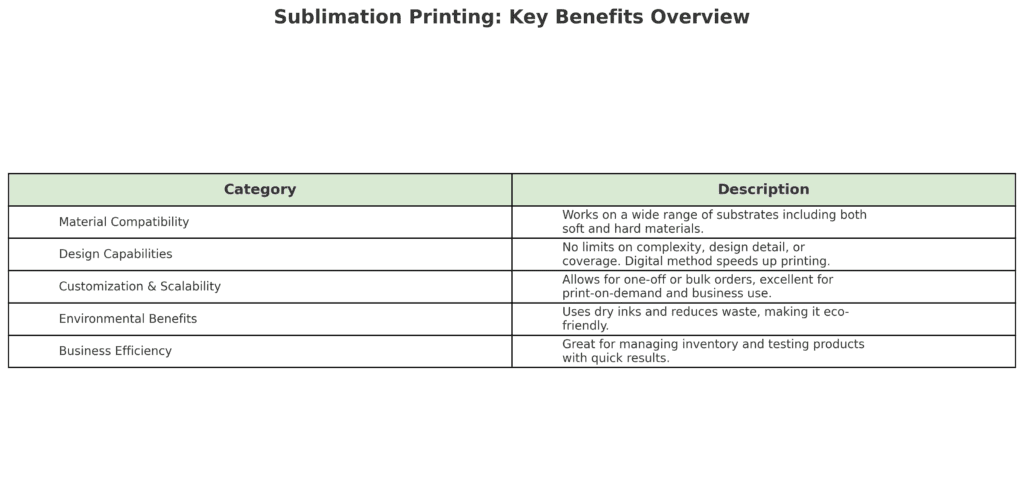

What is sublimation printing? When I first got into sublimation, I was amazed by how this technique could create such vibrant, long-lasting designs on everyday items. Unlike traditional printing, this method uses gas to infuse ink directly into materials like fabrics, plastic, metal, glass, and even ceramics. The process feels almost magical — colors don’t just sit on the surface, they become part of the products. Whether you’re working on custom t-shirts, mugs, tumblers, mouse pads, or signs, the results are consistently sharp, with zero crack or fade even after extended use. This makes it a top choice for personal gifts or commercial offerings alike.

Having worked with both Cricut and Infusible Ink in various projects, I’ve seen the versatility of sublimation stretch across home décor, clothing, and textiles. Since its introduction in the 1950s, this printing method has evolved into a go-to solution for the print-on-demand industry, offering unmatched customization and high-quality output. For small businesses, the ability to deliver stunning, excellent products with rich details has transformed how they approach personalization. With the appropriate tools and gear, newcomers can venture into this imaginative realm and investigate various applications.In my experience, having the freedom to design and experiment with materials has been one of the most fulfilling parts of the journey.

What Is Sublimation Printing? Discover the 4 Magic Steps

Sublimation printing is a process where heat turns ink into gas, bonding it permanently with fabric for vibrant, lasting designs. The 4 key steps include creating the design, printing it onto special paper, applying heat and pressure, and transferring the image onto the fabric. This method is ideal for full-color, fade-resistant prints. At Express Stitch Industries, we offer professional sublimation printing to help bring your custom apparel to life with brilliant, durable results.

How the Sublimation Process Actually Works

In my experience, the magic of sublimation lies in how heat, pressure, and time transform a design into a permanent, vibrant part of the product. You start with special paper and inks made specifically for this technique. Once your artwork is printed, you use a heat press to apply the right temperatures, turning the solid ink into gas through a chemical reaction called a phase transition. The gas then bonds into the polyester or polymer coatings on the fabric, ceramic, or enamel, becoming part of the materials instead of just sitting on top like in traditional screen printing. This fusion makes the print resistant to crack, peel, or rub off and ensures it stays bright and realistic over time.

I’ve used this process for t-shirt, mug, and mousepad designs, and I’ve seen how well it works on polyester-coated rubber and synthetic substrate too. The image becomes embedded, delivering high-quality, crisp results that last even after repeated washing. You’ll notice how the coating helps the dye fully absorb, keeping the print durable and resistant. It’s amazing to see a digital file become a real-life product with such clean color and no fade. If you’ve ever held a well-done sublimated t-shirt or mug, you’ll know just how immersive the final piece can feel.

Step-By-Step Sublimation Printing Process

Step 1: Design the Image

Whenever I begin a sublimation project, I start with Step 1: Design the Image. Creating a good design is more than just visuals—it’s about precision. I use software that allows me to mirror the image, ensuring it’s properly flipped before printing. This matters because when you transfer the design, it appears in reverse if not mirrored. I always choose high-resolution files to maintain clarity in the final print. Once the design is finalized, it’s time to move on to the next step.

Step 2: Printing the Design onto the Sublimation Paper

Printing the Design onto the Sublimation Paper is where the digital idea begins to become physical. I carefully load the sublimation paper into my printer, making sure settings are accurate. This is important because paper alignment and ink flow affect the final result. The design is printed in reverse using sublimation ink, which is formulated to become gas under heat. It’s a small but critical stage in achieving a vibrant and permanent print.

Step 3: Positioning the Design on the Substrate

Next, comes Positioning the Design on the Substrate. I always double-check that the design is correctly aligned on the substrate—whether it’s fabric, polyester, or a coated item like a mug. For uneven or curved surfaces, I use heat-resistant tape to prevent any movement during pressing.

Step 4: The Sublimation Printing Process

Then I go into The Sublimation Printing Process itself. I preheat my heat press to the exact temperature and set the time according to the material type. With the right pressure, I press the design into the surface, watching the magic happen. After cooling, the paper is peeled away to reveal a durable, embedded, and truly eye-catching final result.

What Can You Sublimate On?

After years of working with sublimation and seeing how it transforms everyday objects, I’ve come to appreciate its unmatched flexibility. This printing method stands out in the world of customization because it doesn’t just sit on top of a surface like traditional methods. Instead, it embeds the designs deep into the fabric or material. From apparel to home goods, sublimation unlocks a new level of personalization that’s both durable and long-lasting.

Sublimation in Apparel

When it comes to apparel, the possibilities are truly exciting. Whether it’s t-shirts, hoodies, or sweatshirts, sublimation lets you apply vibrant, bold patterns and photos that remain bright and won’t fade over time. I’ve seen shirts, leggings, dresses, and even swimsuits transformed into walking art pieces. The method works best on polyester fabrics, allowing for seam-to-seam coverage without constraint on the printable area. That’s what makes garment customization with sublimation so powerful—it doesn’t crack or peel, even with frequent use.

Customized Home Décor

Beyond clothing, sublimation is perfect to enhance your living space. I’ve personally custom-designed pillowcases, fleece blankets, and even coasters for clients who wanted their favorite artwork or quote printed onto everyday items. These aren’t just decorations—they’re statements. Think table decorators, stylized details, or eye-catching prints on special surfaces that have a coat to help the design last. With customized home décor, the look is not only unique, but it also feels professional and polished.

Endless Creative Possibilities

My favorite part of this process is how many accessories it can be applied to. Phone cases, polyester hats, tote bags, and even socks can be custom printed with images, logos, or names. I’ve worked with both businesses and individuals to create keychains, decorated drinkware like tumblers, mugs, and cups, and other products that reflect true personality and taste. Thanks to coated surfaces and high-quality results, these prints resist fading and offer endless creative possibilities. It’s not just about function—it’s about expressing life through the essentials we use every day.

Understanding Its Limitations

While sublimation is an excellent technique for producing vibrant, long-lasting prints, it does come with certain limitations that every creator should understand. First, it works best on polyester materials or blends with synthetic fibers, as natural fabrics like cotton, silk, and leather don’t hold the dyes well. This means the print may not appear as bright or durable on these fabrics. Another limitation is that white ink isn’t used in sublimation. So, the designs rely on the background color of the products—blank, light surfaces produce the sharpest results, while black or dark-colored items often appear dull. The final result can really depend on how the color of the fabric interacts with the ink, which is something I’ve learned to work around over time.

There are also technical factors. If a garment is folded or parts remain uncovered, it can lead to creasing and white streaks, especially when aiming for full seam-to-seam coverage. Using a cut and sew technique often ensures better print quality and avoids these flaws. Additionally, sublimation requires specialized equipment like inks, printers, and other printing processes that may not be useful for different tasks. It’s important to know which tools are needed, and how to use them properly to avoid waste. These aspects affect how well your project will turn out and should be factored into your workflow.

Comparing Sublimation, Screen Printing, and DTG

When it comes to custom printing, each method—sublimation, screen printing, and direct-to-garment (DTG)—has its strengths, depending on the material, designs, and business needs. Sublimation works best with polyester and synthetic fabrics or blends, offering photorealistic images, vibrant colors, and smooth gradients. The dye transfer process embeds ink into the fabric, creating washfast, abrasion-resistant prints that won’t fade, crack, or peel over time. It gives seam-to-seam coverage and a full garment print area—something I’ve found especially valuable for bold apparel designs.

The Process and Use Cases

Screen printing, on the other hand, uses a stencil-based ink application with screens and is better for solid or fluorescent colors. It’s highly efficient for bulk orders but involves a time-consuming setup with multiple stencils and longer preparation. While the prints are strong, they can fade or crack with repeated washes. Still, it’s a reliable method for natural fabrics like cotton, linen, and rayon, and suits large-scale branding well if the designs don’t require too much detail.

Which Method Fits Best?

DTG brings in digital inkjet printing, offering high-resolution, intricate designs and full-color capability. It’s great for small runs, custom jobs, and on-demand orders where a quick setup and minimal waste are crucial. It can work on any color of fabric, including dark ones, though the stability of the prints may depend on pretreatment and fabric quality. From my own experience, DTG is ideal for niche products with low per-unit cost-effectiveness concerns, while sublimation remains the top choice for all-over garment designs on light-colored fabrics. Choosing the right method really depends on your production goals, speed, budget, and material type.

Final Thoughts

From my own experience, sublimation is not just a printing method, it’s a smart choice for anyone wanting to bring unique designs to life. It offers seamless, edge-to-edge coverage that’s perfect for all-over-print products, whether you’re designing custom apparel or stylish home decor. It works best with lightweight synthetics, and with the right techniques, you can achieve vibrant, lasting results across various material types. The ability to produce high-quality finishes makes it ideal for people who care about detail and creativity in their work.

If you’re ready to sell, I recommend setting up an online store using a reliable Product Creator to make the process much easier. You can select blanks, customize them, and start creating almost effortlessly. Having the right accessories will refine your workflow, keeping production smooth and consistent. With sublimation, you’re not just making things—you’re opening up endless creative possibilities that are right at your fingertips.

RELEVANT: What Is Screen Printing? 5 Powerful Facts

RELEVANT: Choose Right Clothing Vendor: 10 Positive Steps for Success

FAQ

What is sublimation printing, and how do you choose the right printer?

Unlike standard printers, sublimation printers are built to work with special inks and transfer paper that allow designs to bond permanently with materials. Some people try converting regular printers, but for high-quality, reliable results, it's best to go with trusted brands like Epson or Sawgrass. These industry favorites are designed specifically for sublimation and consistently deliver long-lasting, professional-grade prints.

Which Printing Method Lasts Longer?

Sublimation printing lasts longer because it embeds dye into the fabric, preventing fading, cracking, or peeling. Screen printing is durable too, but may wear over time if not properly maintained.

Is it possible to sublimate on dark fabrics?

Sublimation printing doesn’t work directly on dark fabrics, as the ink needs light-colored material to show up. However, it is possible by first applying a special white vinyl base. This layer allows the sublimation ink to transfer properly, making the design vivid and visible on dark surfaces while still delivering high-quality, lasting results.

Can a Cricut machine do sublimation?

Not by itself—Cricut machines aren’t sublimation printers. However, you can still use them in your sublimation workflow. By using the Print then Cut feature in Cricut Design Space, you can print your design with a sublimation printer and then use your Cricut to cut it precisely using registration marks. This combo allows for clean, professional-looking sublimation projects with detailed edges and custom shapes.

Which is better: sublimation or vinyl?

It really depends on your project and material. Sublimation is ideal for detailed, vibrant designs that last, as the ink fuses directly into the fabric—making it flexible, fade-resistant, and highly durable. Vinyl, while useful for certain applications, rests on top of the material and may crack or peel over time, especially with frequent wear or washing. For long-term quality and design complexity, sublimation usually comes out on top.

Leave a Comment

Your email address will not be published. Required fields are marked *